About Us

Ultiscad is an innovative technology company based in Mansfield, Texas USA, specializing in SCADA, telemetry and remote monitoring and control of industrial systems and processes.

Efficiency and safety are very important aspects of any business operation.

Our SCADA, telemetry and remote monitoring technology helps companies

to achieve efficiency by reducing downtimes, increasing productivity and saving tremendously on planned and unplanned maintenance.

Chemical plants and energy companies spend large amount of money each year conducting periodic manual inspections and monitoring of their assets.

These manual inspections are usually carried out based on a time table of scheduled visits resulting in situations where certain system failure may not be noticed

until the visit is done.

Remote monitoring which is a continuous monitoring system solves this problem by providing instant and timely notification of system failures once they occur.

Ultiscad monitoring systems provide real-time view of your asset, so you know exactly when and where to

allocate resources and perform preventative repairs.

This maximizes system uptime, and overall productivity.

Our systems have proven to provide demonstrable safety, economic, environmental, asset management

and compliance benefits.

Our revolutionary technology has been deployed by multinational companies worldwide.

For our customers

We aim to exceed customer expectations with exceptional levels of quality service and technical support thereby offering the best service and value to our customers. We aim to develop and maintain mutually profitable and lasting relationships with customers and respond to their needs through continuous innovation. We try to build trust between ourselves and all parties with whom we have dealings

For our employees

Ultiscad employs qualified and motivated staff who share our vision and values, work as a team and are committed to success. We aim to offer competitive terms and conditions of employment, seek the welfare of all our staff knowing that they work best when they feel valued, have sense of belonging and can achieve an appropriate work/life balance.

For our shareholders

Ultiscad respects the principle of equal treatment to shareholders, making the relevant information available to all, at the same time in a timely, transparent, complete and accurate manner.

Our Monitoring Technique

At Ultiscad we follow a rule of thumb that with the right sensors, any parameter can be monitored,

depending on the application in question. Parameters are typically selected based on the value of

what they represent.

For instance, in a rotating machinery, monitoring vibration can allow asset health to be determined

in order to prevent unexpected downtime. If vibration level increases above certain limits, it could

suggest that bearings are wearing out.

Also, when moving parts interact, temperature plays a role and a rapid unusual change can

signify impending failure.

These are few examples of what can be monitored depending on the system or machinery,

type and state of materials being handled, and overall system properties.

Services

Cathodic Protection Monitoring

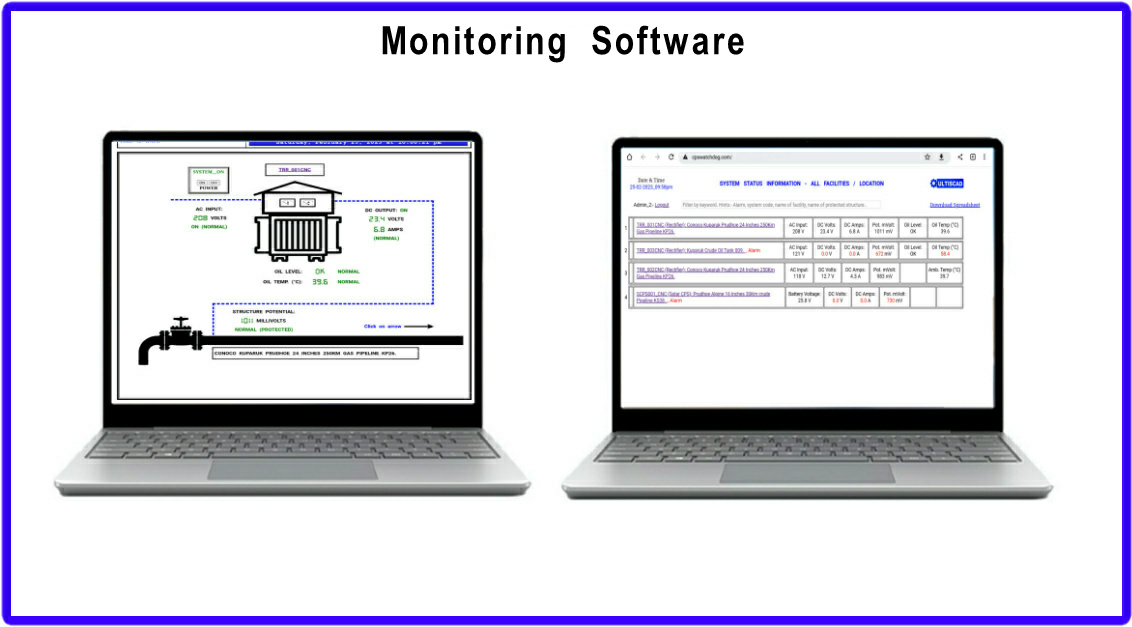

Ultiscad cathodic protection remote monitoring and control system provides customized solution for monitoring

impressed current cathodic protection systems.

System status and performance are monitored online with provision for troubleshooting guides when faults occur.

Utility & Power Monitoring

Ultiscad utility and power systems monitoring solutions enables businesses to become more efficient by providing real-time data viewing

and control of power generation and distribution systems, water management systems and waste management systems.

With Ultiscad, you can have a full view of your utility usage and costs, and take actions to optimize performance, reduce unnecessary expenses,

and minimize environmental impacts and carbon footprint.

Industrial Processes Monitoring

Ultiscad monitoring systems are widely used in various industries to monitor numerous processes such as leaks,

maintenance, vibration, emissions, data, pressure, voltage, level, flow rates, and other parameters.

In maintenance monitoring, monitored data compared with year of manufacture can be used to determine the machine or

component's expected operation life and predict the machine's subsequent breakdown.

Equipment Monitoring

Standalone equipment and systems such as pumps and oil and gas wellheads can be remotely monitored by

Ultiscad system.

Depending on the parameters of interest, specialized sensors are used to carry out the necessary

measurements and data collection.

Our CLients

Contact Us

4313 Aston Lane Mansfield,

76063 TX USA

info@ultiscad.com

+1 682-422-9967